Step 1: Filter Paper Preparation

Prepare the air filter paper in rolls.

Recommended truck air filter paper: fully glued paper, uncured filter paper; The filtration grade is chosen between F8 and F9. If it's too low, the filter rating is insufficient; if it's too high, the intake air volume is inadequate. Typically, it is thicker than car air filter paper.

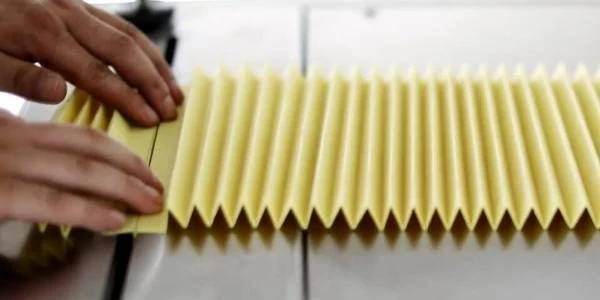

Step 2: Filter Paper Pleating

Pleat the truck air filter paper to increase the filtration area, thereby capturing more dust and particles while reducing airflow resistance. Additionally, the pleated structure can enhance the mechanical strength of the filter element, making it more capable of withstanding the vibrations and pressure changes in the truck's working environment.

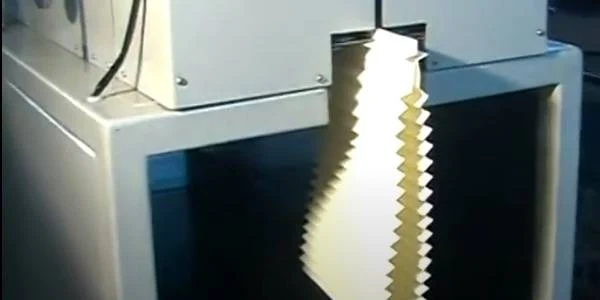

Step 3: Filter Paper Cutting

Cut the pleated truck air filter paper to meet the size and shape requirements of specific filter elements, to fit different models and brands of truck engine air filters.

Step 4: Filter Paper Bonding

Bond the pleated and cut filter paper with hot melt adhesive, to ensure the structural stability and sealing of the filter element, thereby improving the overall performance of the air filter.

Hot melt adhesive recommendation: There are three material options: EVA, PO, and PA. Among them, EVA has the highest cost performance, PO hot melt adhesive has better moisture resistance, and PA hot melt adhesive has better high-temperature resistance. You can choose according to the actual situation.

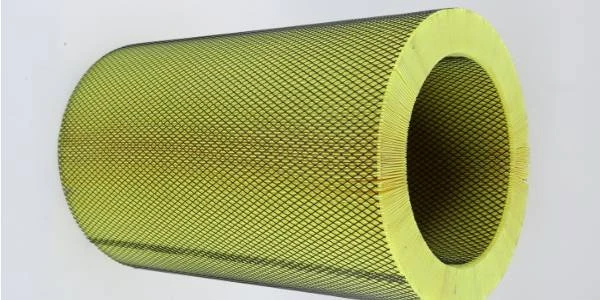

Step 5: Inner & Outer Mesh Production

The inner and outer mesh can be made of perforated metal mesh or expanded metal mesh, which can protect the filter from deformation and improve the filter's impact resistance and service life. It is an important component for internal support and external protection of the filter.

Inner and outer mesh recommendation: perforated metal mesh or expanded metal mesh, made of galvanized or stainless steel plate.

Step 6: Filter Paper, Inner & Outer Mesh Assembly

The truck air filter paper, inner and outer mesh assembly is a critical step in the production of air filter elements. This process involves combining the treated filter paper with the inner and outer mesh that supports its structure to form a complete filter element assembly.

Step 7: Metal End Cap Stamping

The metal end cap is formed through a stamping process and is ultimately used to seal both ends of the filter to ensure the structural integrity and sealing of the filter.

Metal end cap recommendation: Customers need to provide the OEM number to determine the exact dimensions and pricing.

Step 8: Metal End Cap Bonding

The bonding of the metal end cap of the truck air filter is one of the key steps in the filter manufacturing process, ensuring the overall sealing and structural stability of the filter.

Recommended adhesive for metal end caps: Two-component PU adhesive is more suitable for high viscosity, high temperature, and high strength bonding. It is moderately priced, making it the most cost-effective.

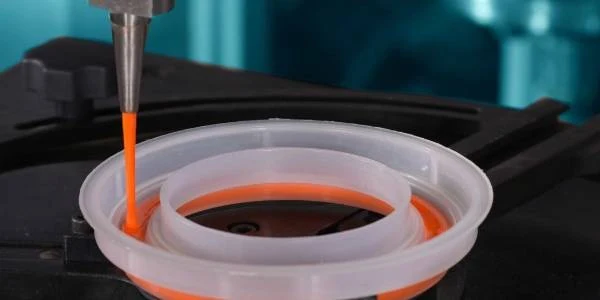

Step 9: Seal Ring Bonding

The bonding process of the truck air filter seal ring is one of the key steps to ensure the filter achieves optimal sealing performance. In this process, the seal ring not only plays an important role in preventing air leakage but also directly affects the overall durability and filtration efficiency of the filter.

Recommended rubber seal: Silicone material, customized to specific dimensions based on the OEM number you provide.

Recommended adhesive for gasket: We recommend LM1011 and LM1012, two commonly used products, specifically for bonding between metal end caps and rubber seal rings.

Step 10: PU End Cap Molding

We use PU glue for plastic end caps, which is widely used in the manufacturing of air filter end caps due to its excellent elasticity, wear resistance, and chemical corrosion resistance. For end cap mold, we use high-precision CNC machining technology to manufacture molds, ensuring the accuracy and consistency of the end cap shape.

PU adhesive recommendation: You can choose based on your specific operation process, curing time requirements, etc.

Plastic mold recommendation: You only need to provide the OEM number, and we can customize and produce it for you.

Step 11: PU End Cap Curing & Trimming

The curing and trimming process of the PU end cap of the truck air filter is a key step to ensure the end cap has optimal performance and appearance quality. This process not only relates to the final physical properties of the end cap but also directly affects the sealing effect and service life of the filter.

Step 12: Filter Element Gluing

Applying adhesive to the filter element can ensure a firm connection between parts and overall sealing performance. Through precise adhesive application, the filtration efficiency and service life of the filter can be effectively improved.

Hot melt adhesive recommendation: There are three material options: EVA, PO, and PA. Among them, EVA has the highest cost performance, PO hot melt adhesive has better moisture resistance, and PA hot melt adhesive has better high-temperature resistance. You can choose according to the actual situation.