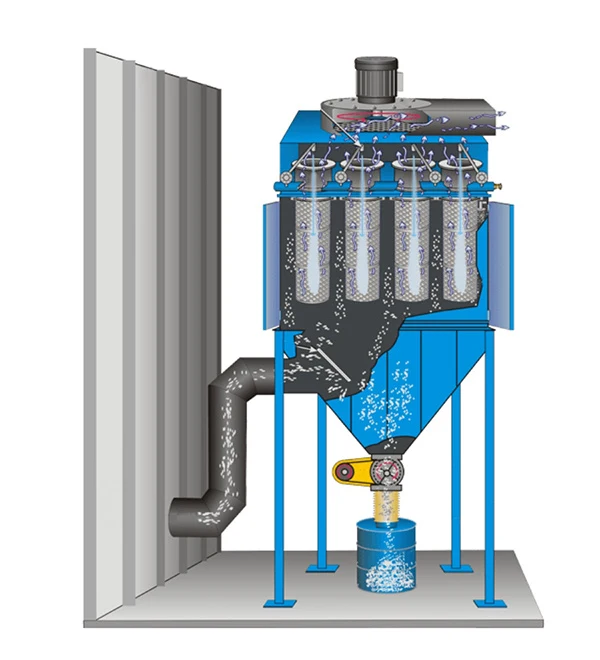

Bag-type dust collector system

Technological innovation has driven the enhancement of environmental standards, injecting new vitality into sustainable development. Technological innovations in dust removal filtration are primarily focused on the research and development of filter materials and manufacturing processes. By introducing and assimilating advanced international technologies, continuous optimization of filter bag and filter cartridge materials is achieved, such as using more efficient filter materials and developing products that adapt to extreme conditions such as high temperature and high corrosion. In addition, the application of new nanotechnology and superfine fiber technology has further improved dust removal efficiency and extended the service life of filter bags and filter cartridges, reducing maintenance costs.

PLM Filter provides more diversified and customized products tailored to the specific needs of different industries and working conditions. We have a comprehensive supply chain system, an excellent technical team, and keen market insight. Through continuous product improvement and innovative solutions, we meet the ever-changing market demands.

PLM Filter's filter material and accessory products are widely used in bag-type dust collector systems and cartridge-type dust collector systems, dedicated to providing efficient dust removal solutions to help various industrial facilities improve air quality, reduce pollutant emissions, and comply with environmental protection requirements. Bag -type dust collectors and cartridge-type dust collectors, as common industrial dust removal equipment, are widely used in industries such as metallurgy, chemical, cement, and power. PLM Filter's filtration products play a critical role in these systems.

Bag-type dust collector system

Cartridge-type dust collector system

As a supplier of dust removal filtration materials and accessories, PLM Filter always focuses on customer needs, providing efficient and durable filter materials and accessories to help customers improve production efficiency and ensure environmental compliance. We continuously develop and improve products to provide customers with excellent filtration solutions, reducing equipment downtime and lowering operating costs. For the industry, we actively promote technological advancement, improve filter material performance, and enhance the overall professional level of the industry through knowledge sharing and training, promoting the sustainable development of the industry.

Our customers come from all over the world, including countries and regions such as Thailand, Vietnam, the United Arab Emirates, and the United States.

Thailand Goldentex Pro

Vietnam Tan Thanh

United States AJR Filtration

United States Filterbag

United Arab Emirates Unitech

United States Fabrics for Industry

Hungary Indufil

Poland GEKO FILTRATION

United States Material Motion

India Shimi

United States Imperial

United States Pleatco

Australia Clyde-Apac

Sweden Camfil APC

United States Hengst Filtration

Our dust removal filtration materials and accessories are suitable for all common filter bag dust collectors and filter cartridge dust collectors in the market, such as C&W, Downflo, Camfil Group, Nederman, etc.

A customer from Iran, specializing in the production and sales of dust removal equipment and related spare parts, is quite well-known locally. In our communication, they expressed that the demand for dust collector filter bags from customers is very diverse, and they hoped we can provide a detailed specification and requirements of dust collector filter bags in different fields or working environments based on consumer needs. With years of industry expertise and experience, we provided customers with a very clear performance sheet of filter fabric for dust collector filter bags, which won their favor. After a period of consideration, the customer finally chose us and expressed a willingness for continuous cooperation.