Heat setting treatment

For various industries and complex conditions, PLM Filter offers a diverse and customized range of filter fabric for dust collector filter bags. For medium temperature environments such as chemical, machining, and ore mining industries, we offer products such as polyester, polypropylene, and nylon; For high temperature environments such as thermal power generation, steel smelting, and cement manufacturing, we provide high-temperature resistant filter fabrics such as PPS and PTFE; For special conditions, we also offer antistatic, PTFE membrane, waterproof, oil-proof and other special filter fabrics, suitable for high air volume, high temperature, high humidity, and highly corrosive gas filtration. PLM Filter uses needle-punch technology for filter fabric for dust collector filter bags, which features good air permeability, low resistance, simple production process, and low cost.

With rich industry experience and knowledge, PLM Filter quickly selects the right products for you and provides technical support.

Excellent Acid & Alkali Resistance

Flame Retardant & High-Temperature Operation

Economical & Wide Applications

Sturdy & Wear-Resistant

High Filtration Performance

Excellent Dust Removal Performance

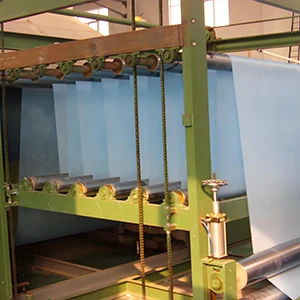

Heat setting treatment

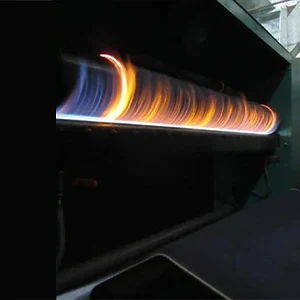

Singeing treatment

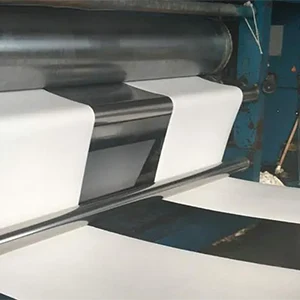

Calendering treatment

Impregnation treatment

Coating treatment

Conductive treatment

| Code Number | Composition | Air permeability (L/m 2/s) |

Weight (g/m2) | Breaking Strength (N/5/20cm ) | Elongation at Break (%) | Operating Temperature (°C) | Surface Treatment | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Fiber + Base fabric | Warp | Weft | Warp | Weft | Continuous | Instantaneous | ||||

| LMPO-PO-250 | Polyester + Polyester | 150–250 | ≥ 500 | ≥ 1100 | ≥ 1600 | ≤ 35 | ≤ 50 | 130 | 150 | Heat setting, singeing, calendering, water and oil repellent, membrane, impregnation |

| LMPM-PM-350 | Acrylic + Acrylic | 200–350 | ≥ 500 | ≥ 700 | ≥ 800 | ≤ 20 | ≤ 40 | 120 | 140 | Heat setting, singeing, calendering, water and oil repellent, membrane, impregnation |

| LMPP-PP-250 | Polypropylene + Polypropylene | 150–250 | ≥ 500 | ≥ 1500 | ≥ 1500 | ≤ 35 | ≤ 50 | 90 | 95 | Heat setting, singeing, calendering, water and oil repellent, membrane, impregnation |

| LMPT-PT-250 | PTFE + PTFE | 150–250 | ≥ 750 | ≥ 700 | ≥ 800 | ≤ 15 | ≤ 30 | 260 | 280 | Heat setting, PTFE membrane, PTFE emulsion impregnation |

| LMPI-PI-300 | Polyimide + Polyimide | 150–300 | ≥ 500 | ≥ 800 | ≥ 1000 | ≤ 20 | ≤ 40 | 260 | 280 | Heat setting, PTFE membrane, PTFE emulsion impregnation |

| LMBA-BA-400 | Basalt + Basalt | 150–400 | ≥ 700 | ≥ 1900 | ≥ 2000 | ≤ 10 | ≤ 10 | 330 | 350 | Heat setting, PTFE membrane, PTFE emulsion impregnation |

| LMAF-AF-250 | Aramid + Aramid | 150–250 | ≥ 500 | ≥ 800 | ≥ 1000 | ≤ 35 | ≤ 45 | 204 | 240 | Heat setting, singeing, calendering, water and oil repellent, membrane, impregnation |

| LMAF-GF-300 | Aramid + Fiberglass | 150–300 | ≥ 650 | ≥ 1000 | ≥ 1200 | ≤ 40 | ≤ 50 | 210 | 250 | Heat setting, singeing, calendering, water and oil repellent, membrane, impregnation |

| LMAF-PT-60 | Aramid + PTFE | 30–60 | ≥ 550 | ≥ 800 | ≥ 1000 | ≤ 35 | ≤ 45 | 204 | 240 | Heat setting, singeing, calendering, water and oil repellent, membrane, impregnation |

| LMAFGF-GF-300 | Aramid, Fiberglass + Fiberglass | 150–300 | ≥ 850 | ≥ 2200 | ≥ 2100 | ≤ 10 | ≤ 10 | 220 | 260 | Heat setting, singeing, calendering, water and oil repellent, membrane, impregnation |

| LMPPS-GF-300 | PPS + Fiberglass | 150–300 | ≥ 850 | ≥ 2200 | ≥ 2100 | ≤ 10 | ≤ 10 | 200 | 230 | Heat setting, singeing, calendering, water and oil repellent, membrane, impregnation |

| LMPPS-PPS-60 | PPS + PPS | 30–60 | ≥ 550 | ≥ 900 | ≥ 1200 | ≤ 20 | ≤ 35 | 120 | 140 | Microfiber, PTFE microporous membrane, PTFE coating, PTFE emulsion impregnation |

| Note: The above are some common specifications and parameters. If you do not find a suitable product, you can contact our sales staff for detailed inquiries. Contact Us | ||||||||||

In the field of filter fabric for dust collector filter bags, various factors such as different filtering gases, different dust properties, different cleaning methods, different operating systems, and special working conditions, all become considerations for selecting filter fabric for dust collector filter bags. To help you choose the most suitable product type, we will recommend the most appropriate product based on your specific needs and provide comprehensive technical support.

We are committed to providing you with the most professional service and the highest quality products. We look forward to cooperating with you. If you have any questions or needs, please feel free to contact us.

PLM Filter provides customized solutions for dust collector filter bag manufacturers (including sample testing and customization) to meet specific customer needs.