Providing Full-Process Technical Guidance For Air Filter Production Line

As a part of the automotive parts industry, the market for car air filters has been growing steadily with the increasing global car ownership, leading to a rising demand year by year. Accompanying the development of car air filters, PLM Filter has been deeply involved in the field of car air filter materials and accessories for many years. With rich practical experience, outstanding technical strength, and market insight, PLM Filter has integrated multiple cutting-edge technologies in the field of car air filter materials and accessories. The company is committed to creating an efficient, eco-friendly, and sustainable supply chain for car air filters, bringing innovative development to the industry.

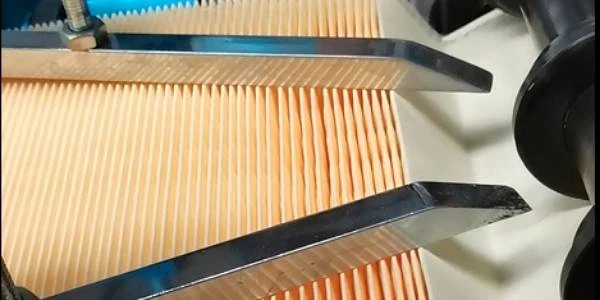

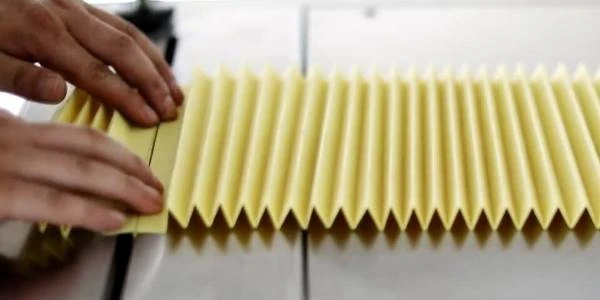

In addition to filter materials and accessories, PLM Filter also offers advantageous products such as paper pleating machines, cutting machines, hot melt molding machines, and frame trimming machines. Not only has it significantly improved production efficiency, but it has also reduced production costs, creating tremendous value for customers.

Recommendation for OEM Products

Recommendation for Aftermarket

Recommendation for Different Regions

Recommendation for Different Working Environments