Step 1: Pleating

Use a fully automatic edge pleating machine to pleat the glass fiber filter material, providing a larger filtration area for the glass fiber filter material, while reducing the system's pressure loss and extending the filter element's service life.

Hydraulic glass fiber recommendation: Specific recommendations based on your required filter rating, working pressure, working temperature, and filtration medium.

Step 2: Cutting

Use a slitting machine to cut the pleated glass fiber filter material, ensuring that the size and edges of each piece of filter paper meet the design standards.

Step 3: Hydraulic Filter Paper Trimming

Use a mesh edge trimming machine to trim the glass fiber filter material and cut off the excess parts to ensure the glass fiber filter material is precise and tidy, allowing the filter element to fit tightly with the frame and improving overall sealing performance.

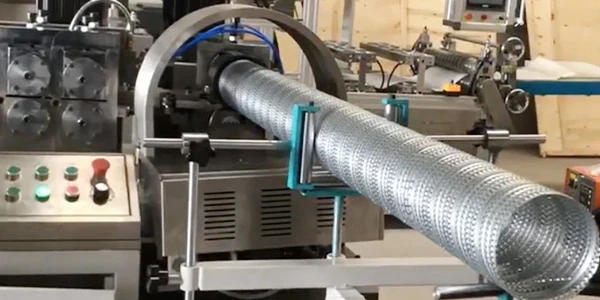

Step 4: Central Support Spiral Perforated Metal Fabrication

Use a hydraulic oil filter manufacturing machine to make galvanized sheets into spiral perforated metal. It can be used both as a support central tube and an outer mesh to protect the filter, bearing pressure.

Spiral perforated metal recommendation: stainless steel material, size and filter rating produced according to customer requirements. If you need, you can directly contact our sales staff.

Step 5: Metal End Cap Stamping

The metal end cap is made of galvanized steel plate material by using a stamping machine, used to seal both ends of the filter paper and filter screen, ensuring that all gas passes through the filter without leakage.

Metal end cap recommendation: Materials include stainless steel plate, galvanized steel plate, anti-fingerprint steel plate. You only need to provide the OEM number, and we will customize the design and production for you.

Step 6: End Cap Gluing

Use an automated gluing equipment to apply two-component filter element adhesive or single-component thermosetting adhesive between the end cap and filter element for bonding, to ensure the overall sealing and durability of the filter.

Two-component filter element adhesive recommendation: Two-component PU adhesive is more suitable for high viscosity, high temperature, and high strength bonding. It is moderately priced, making it the most cost-effective.

Single-component thermosetting adhesive recommendation: LM1712, specially designed and produced by PLM Filter for end caps, is simple and convenient to use.

Step 7: Filter Element Gluing

Filter element gluing can ensure a firm connection between parts of the filter element and overall sealing performance. Through precise gluing operations, the filter rating and service life of the filter can be effectively improved.

Hot melt adhesive recommendation: There are three material options: EVA, PO, and PA. Among them, EVA has a higher cost-performance ratio, PO hot melt adhesive has better moisture resistance, and PA hot melt adhesive has better high-temperature resistance. You can choose according to the actual situation.