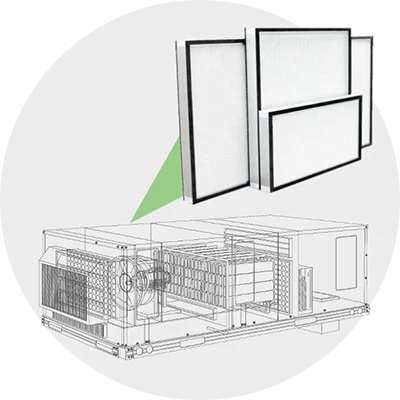

Step 1: Filter Fabric Preparation

Prepare the filter fabric materials used for making primary, medium, and high-efficiency air filters. Depending on the requirements and usage, filter fabric can be divided into pre filter fabric, medium-efficiency filter fabric, high-efficiency & ultra-high-efficiency filter fabric, etc.

Filter fabric recommendation: We will recommend different filtration grades, different surface treatments, and different materials of filter fabric based on your specific situation.

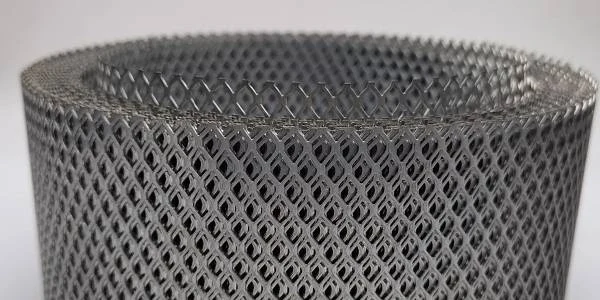

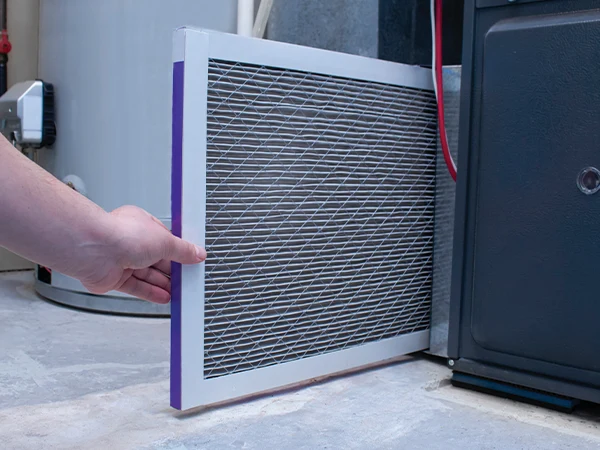

Step 2: HEPA Filter Support Grid

Prepare the HEPA filter support grid, to provide support and protection for the filter material.

HEPA filter support grid recommendation: expanded metal mesh, aluminum plate mesh, PVC coated wire mesh, fine mesh, etc. Recommendations are mainly based on your needs and specific working environment. If needed, you can directly contact our sales staff for consultation.

Step 3: Filter Material Assembly

Assemble the filter fabric and the filter support grid together.

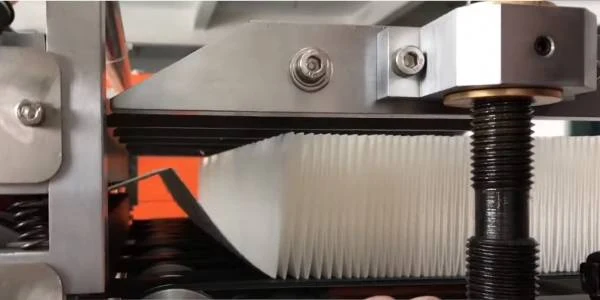

Step 4: Filter Material Pleating

Pleat the filter material, thus capturing more dust and particulates while reducing airflow resistance. In addition, the pleated structure can also enhance the mechanical strength of the filter element, making it more capable of withstanding vibrations and pressure changes in the working environment.

Step 5: Cutting

Cut the pleated filter fabric to meet the size and shape requirements of specific filter elements, to fit different models and brands of air filters.

Step 6: Spraying Frame Glue

Use a fully automatic gluing machine to apply glue between the frame and the filter media, forming adhesion and sealing.

Frame recommendation: Frames are divided into metal frames, paper frames, and plastic frames. We usually recommend cost-effective paper frames for primary and medium-efficiency filters; while metal frames are suitable for filters of any filter grade; plastic frames are mainly suitable for medium, high, and ultra-high-efficiency filters.

Two-component adhesive recommendation: Two-component PU adhesive is more suitable for high viscosity, high temperature, and high strength bonding. It is moderately priced, making it the most cost-effective.

Step 7: Spraying Line Glue

In the manufacturing process, the filter material needs to be securely adhered to the filter frame, which requires the use of a specific adhesive—namely, line glue. A dispensing machine is used to spray line glue inside the filter to fix the filter material to the frame.

Hot melt glue recommendations: There are three material options – EVA, PO, and PA. Among them, EVA offers a higher cost-performance ratio, PO hot melt glue has better moisture resistance, and PA hot melt glue has superior high-temperature resistance. Selection can be made based on actual conditions..