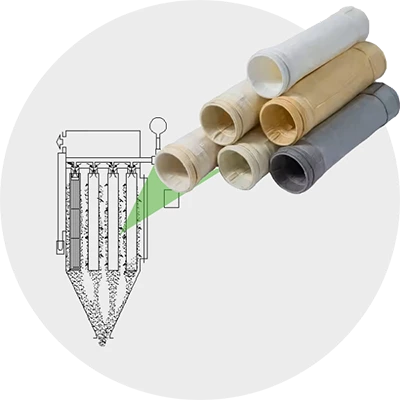

Provide a Full Range of Filter Fabric for Dust Collector Filter Bags

With the increasing global awareness of environmental protection, governments worldwide have introduced a series of stringent environmental protection regulations that require companies to reduce pollutant emissions, thereby driving the demand for dust collector filter bags. At the same time, the growth of industrial sectors, especially high-pollution industries such as steel, cement, chemical industry, and electric power, is the main driving force for the development of the dust collector filter bags market.

In the face of a continuously growing market environment, PLM Filter actively arranges its product portfolio. Currently, we can provide a full range of filter materials for dust collector filter bags as well as one-stop procurement services and solutions, and offer comprehensive technical support. We have been engaged in air filtration materials and accessories for many years, possessing extensive knowledge and experience. Our professional technical and service team aims to help enterprises maintain a leading competitive edge in a rapidly growing environment.

Recommendation for OEM Products

Recommendation for Aftermarket

Recommendation for Different Regions

Recommendation for Different Working Environments