Add flame retardants to inhibit the oxidation reaction that leads to combustion.

- Home

- Filter Material

-

Typical Process

-

Car Air Filter Production Process

-

Truck Air Filter Production Process

-

Cabin Air Filter Production Process

-

Spin-On Fuel & Oil Filter Production Process

-

Eco-Friendly Fuel & Oil Filter Production Process

-

Toyota Car Oil Filter Production Process

-

Toyota Car Fuel Filter Production Process

-

Hydraulic Filter Production Process

-

Dust Collector Filter Bag Production Process

-

Dust Collector Filter Cartridge Production Process

-

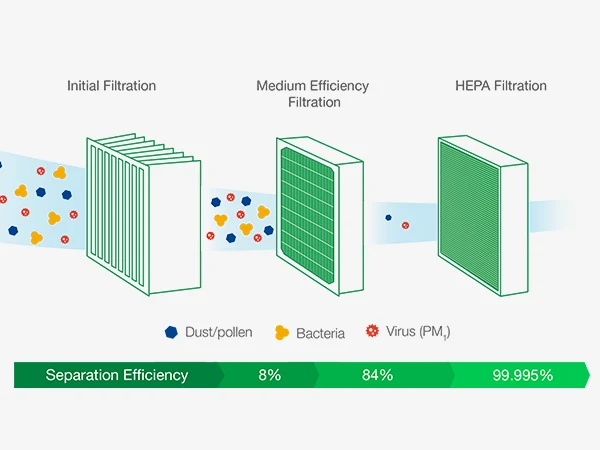

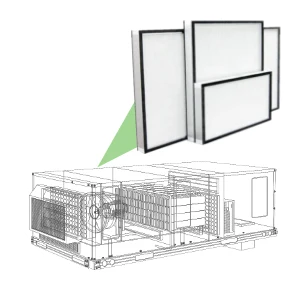

Primary, Medium & High-Efficiency Filters Production Process

-

- Industry

- Resources

- About

- Contact