Step 1: Filter Paper Preparation

Prepare oil or fuel filter paper in rolls, which is the foundation of the entire production process. This is a critical step to ensure that the filter can effectively filter out impurities and contaminants from fuel and oil during the manufacturing process.

Fuel and oil filter paper recommendation: Typically, standard fuel and oil filter paper is used, cured with phenolic resin, offering a high cost-performance ratio.

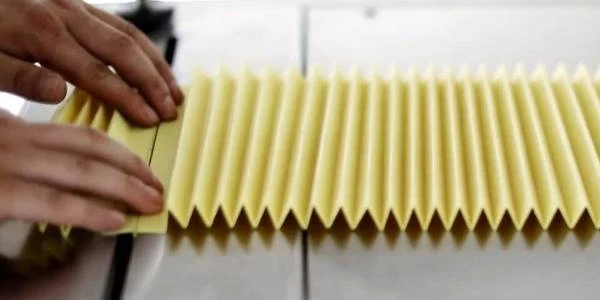

Step 2: Filter Paper Pleating

Use an automatic pleating machine to evenly pleat the filter paper, ensuring consistent spacing and tight arrangement, to maximize its effective filtration area, thereby enhancing the filter paper's dirt holding capacity and ensuring efficient filtration of fuel and oil.

Step 3: Filter Paper Cutting

Use a filter paper cutting equipment to precisely cut the filter paper to ensure that each piece meets the design standards in terms of size and edges.

Step 4: Center Tube Production

It is made of stainless steel material by fully automatic spiral center tube making machine. It can not only serve as a support center tube, but also can act as an outer mesh to protect the filter and withstand pressure.

Spiral perforated mesh recommendation: Stainless steel material, dimensions, and filter rating shall be produced according to customer requirements. If you need it, you can directly contact our sales personnel.

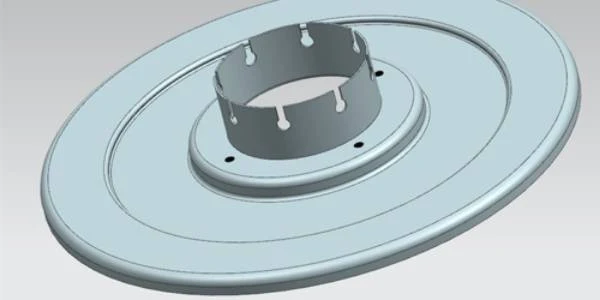

Step 5: End Cap Stamping

The metal end cap is made of galvanized steel sheet material by using a stamping machine to seal both ends of the pleated filter element, ensuring that all gas passes through the filter without leakage.

Metal end cap recommendation: Materials include stainless steel sheets and galvanized steel sheets. You only need to provide the OEM number, and we will customize the design and production for you.

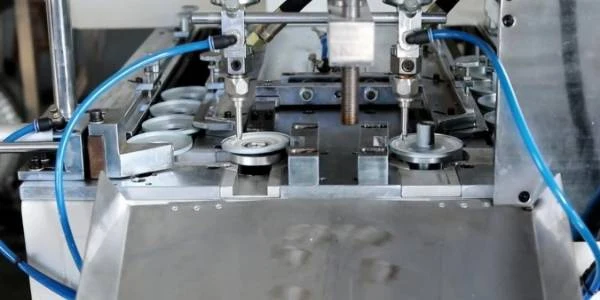

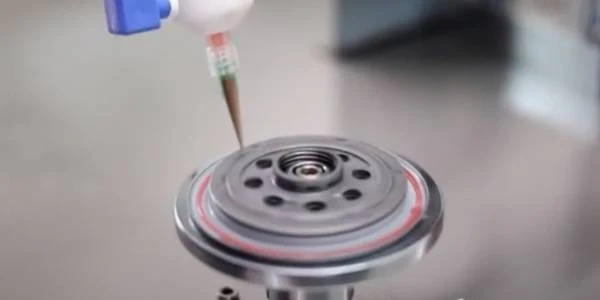

Step 6: End Cap Bonding

Use an automated dispensing equipment and apply two-component filter element adhesive or single-component thermosetting adhesive between the end cap and filter element for bonding to ensure overall filter sealing performance and durability.

Two-component filter element adhesive recommendation: Two-component PU adhesive is more suitable for high viscosity, high temperature, and high strength bonding, with moderate price, making it the most cost-effective.

Single-component thermosetting adhesive recommendation: LM1712, PLM Filter specially designed and produced for end caps, easy to use.

Step 7: Spring Production

The spring is a key component of spin-on fuel and oil filters. Its function is to secure the filter element inside the metal housing during vibration and oil flow. Springs in filters are usually made of stainless steel or alloy steel.

Spring recommendation: You only need to provide the product's OEM number, and we will custom design and produce it for you. Materials include stainless steel, carbon steel, and alloy steel.

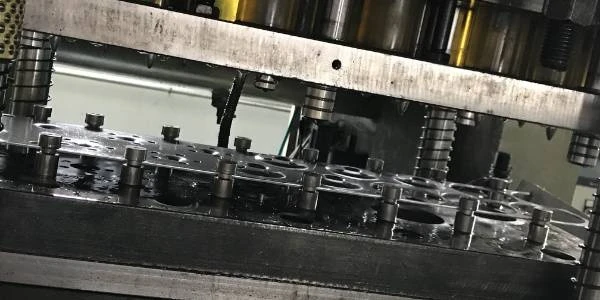

Step 8: Housing Manufacturing

The housing is made of high quality steel by using a multi-station automatic drawing machine. It is a filter component used to house the filter element or filter element assembly, maintaining system and filter internal pressure operation.

Housing recommendation: Made with high-quality steel. Simply provide the OEM number, and we will customize the production for you.

Step 9: Bypass Valve Stamping Part

The bypass valve stamping part is made of high-quality galvanized steel by using a press machine, fully automatic rotary table bypass valve welding machine, fully automatic rotary table bypass valve riveting machine, and other mechanical equipment. It is located on the spin-on fuel and oil filter. When the filter element is clogged and the fuel or oil pressure reaches 100±20 kPa, the bypass valve automatically opens, allowing the fuel or oil to flow through.

Bypass valve recommendation: Just provide the OEM number, and we can customize production for you. If needed, please contact our sales personnel.

Step 10: Cover Plate & Seal Plate Production

The cover plate and seal plate are made of galvanized steel sheet by using equipment such as press machines, projection welding machines, and fully automatic six-station rotary tapping machines. They are used for spinning onto the filter to prevent gasket sealing surface deflection (movement) and to provide a secure threaded connection for the engine.

Cover plate and seal plate recommendation: Just provide the OEM number, and we can customize production for you. If needed, please contact our sales personnel.

Step 11: Cover Plate Gluing

Use an automatic sealing plate gluing machine to apply anaerobic adhesive on the cover plate and seal plate, and bond and seal with the housing.

Anaerobic adhesive recommendation: Anaerobic adhesive is specialized for bonding and sealing between metal surfaces. We recommend using the LM1013 product, which is specifically designed for bonding the cover plate of spin-on fuel and oil filters.

Step 12: Filter Element & Housing Assembly

Use a fully automatic multifunctional sealing machine to assemble the filter element and housing together, and then utilize a multifunctional screen printing machine to print various required information on the housing, such as model, size, etc.

Step 13: Seal Ring Assembly

The automatic seal assembly production line places the rubber seal ring into the manufactured fuel or oil filter, serving to seal the filter port.

Rubber seal ring recommendation: Color and size can be customized according to user requirements.

Step 14: Testing & Packaging

The produced spin-on fuel and oil filters cannot be directly marketed; they must undergo testing and packaging, which are key steps to ensure product quality and user safety.