| Luxury cars, aircraft cockpits |

F8, F9, H10 |

Partition or non-partition bag filters, cartridge filters |

Flame-retardant, odorless |

| General clean room |

F8, F9, H10 |

Partition or non-partition bag frame filters |

Long lifespan, odorless |

| Class 300,000 pharmaceutical workshop |

F8, F9, H10, H11 |

Bag frame filters, non-partition or partition frame filters |

Fiber-free, dust-free, sterilized, no organic matter |

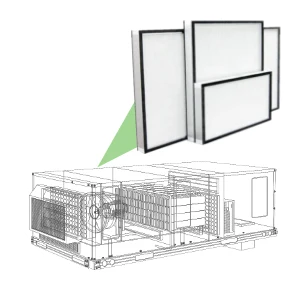

| Class 100,000 and Class 10,000 clean rooms |

HEPA |

Partition or non-partition high-efficiency panel frame filters |

100% tested flame-retardant material, long lifespan |

| Class 100 clean room |

HEPA or ULPA |

Partition or non-partition high-efficiency or ultra-high-efficiency filters |

100% tested |

| Electronic chip workshop |

HEPA |

Partition or non-partition high-efficiency filters |

High-speed inlet air, long lifespan |

| Class 10 and Class 1 chip clean room |

ULPA |

Non-partition Ultra-high-efficiency Filters |

Uniform speed, high-speed inlet air, long lifespan |

| Purification workbench air shower room |

HEPA |

Partition or non-partition frame filters |

Multi-directional blowing |

| Air purifier |

HEPA |

Office, residential, automotive, commercial, etc., different forms |

PM2.5 prevention, odor prevention, bacteria prevention |

| Protective mask |

HEPA |

Partition or non-partition frame filter, pleated tubular filters |

Non-toxic,anti-fogging (cmoisture-proof) |