Step 1: Filter Material Preparation

There are various options for the raw materials used to make filter cartridges, commonly including filter paper and filter fabric. When selecting raw materials, it is necessary to choose according to the different uses and performance requirements of the filter cartridges.

Filter paper recommendation: Wood pulp fiber filter material is mainly used for gas turbines, centrifugal air compressors, and other large units' inlet filtration and sandblasting dust removal for large particle low concentration dust media.

Filter fabric recommendation: Commonly used are polyester fiber and PP fiber non-woven fabric, suitable for most applications.

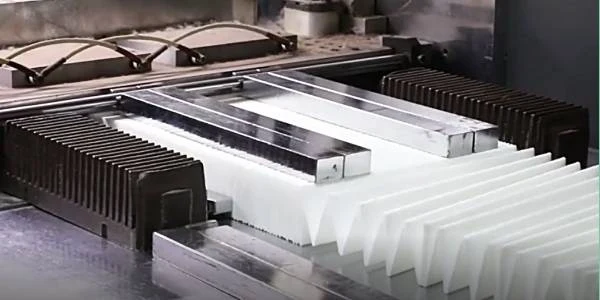

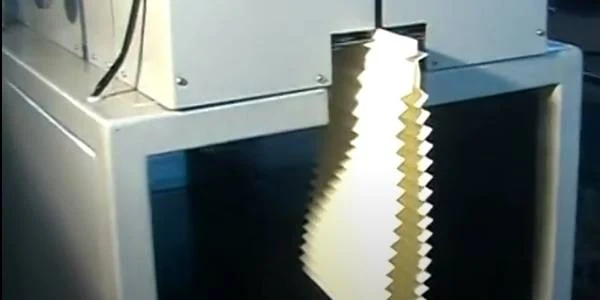

Step 2: Pleating & Forming

The cut filter material is processed through a pleating machine to increase the surface area of the filter media, thereby improving filtration efficiency. This step determines the number of pleats and the filtration area of the filter cartridge.

Step 3: Filter Material Cutting

According to the size of the filter cartridge, the filter material is cut into appropriate sizes and shapes, usually using a cutting machine for precise trimming.

Step 4: Filter Material Bonding

The pleated and cut filter paper is bonded with hot melt adhesive, ensuring the structural stability and sealing of the filter element to enhance the overall performance of the air filter.

Hot melt adhesive recommendation: There are three material options: EVA, PO, and PA. Among them, EVA offers a higher cost-performance ratio, PO hot melt adhesive has better moisture resistance, and PA hot melt adhesive has better high-temperature resistance. Selection can be made based on actual conditions.

Step 5: Inner &Outer Mesh Fabrication

The inner and outer mesh can choose perforated metal mesh or expanded metal mesh, which can protect the filter from deformation, enhance the filter's impact resistance and service life. They are important components for internal support and external protection of the filter.

Inner and outer mesh recommendation: Perforated metal mesh or expanded metal mesh, made of galvanized or stainless steel plate.

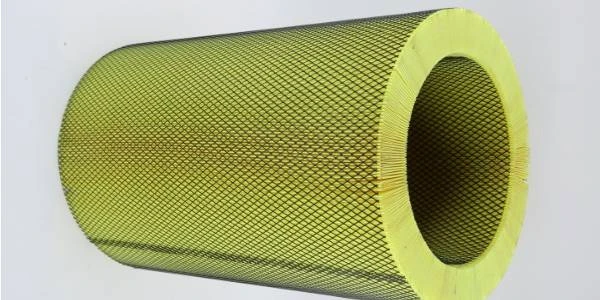

Step 6: Filter Element & Metal Mesh Assembly

This process involves combining the treated filter material with the inner and outer mesh that supports its structure to form a complete filter cartridge assembly.

Step 7: Metal End Cap Stamping

The metal end cap is formed through a stamping process and is ultimately used to seal both ends of the dust collector filter cartridge to ensure the structural integrity and sealing of the dust collector filter cartridge.

Metal end cap recommendation: Customers need to provide the specific dimensions of the dust collector filter cartridge.

Step 8: End Cap Bonding

End caps are installed at both ends of the filter material, typically using a special adhesive to tightly bond the end caps with the filter material. The material of the end cap can be metal, plastic, or rubber, and different materials are chosen based on specific applications.

Recommended adhesive for metal end caps: Two-component PU glue is more suitable for high viscosity, high temperature, and high strength bonding. It is moderately priced, making it the most cost-effective.

Step 9: Filter Element Gluing

Filter element gluing can ensure a firm connection between parts of the filter element and overall sealing performance. Through precise glue application, the filter rating and service life of the filter can be effectively improved.

Hot melt adhesive recommendation: There are three material options: EVA, PO, and PA. Among them, EVA offers a higher cost-performance ratio, PO hot melt adhesive has better moisture resistance, and PA hot melt adhesive has better high-temperature resistance. Selection can be made based on actual conditions.