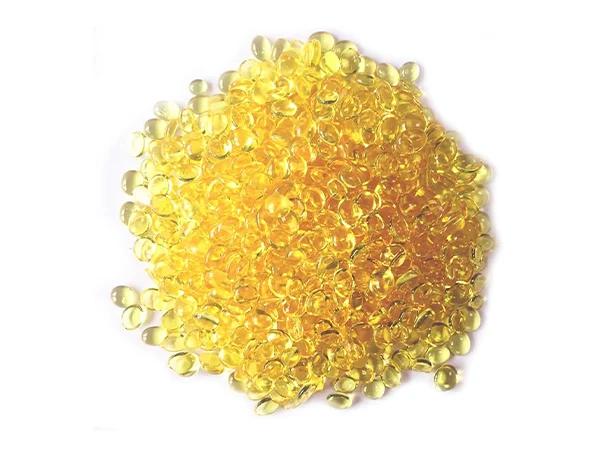

Air filter center line adhesive

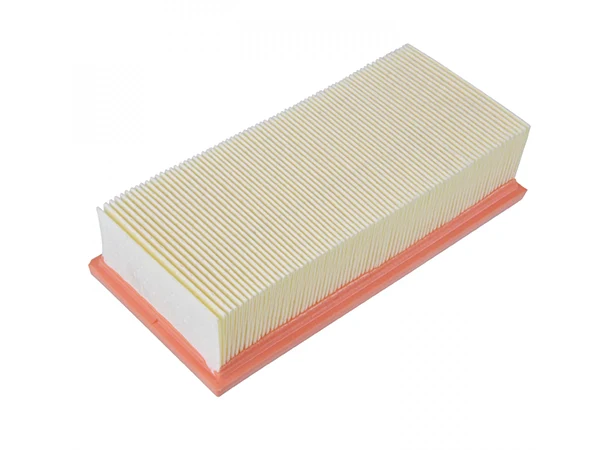

Due to the complexity of the working environment of automotive filters, hot melt adhesives used in automotive filters face numerous challenges, including high temperature resistance, cold resistance, and low volatility. Our hot melt adhesive specifically designed for automotive filter assembly offers excellent adhesion, and is suitable for bonding paper and plastic, making it an ideal choice for center line adhesive, paper pleating adhesive, and edge banding adhesive. This product has excellent thermal adhesion and outstanding temperature resistance, further enhancing its versatility and processability. Besides, it is solvent-free, safe, and environmentally friendly.

PLM Filter provides high and low-temperature resistant, solvent-free, stable performance, and cost-effective hot melt adhesive solutions for the OEM and aftermarket of the automotive filter industry. We are not only a filter material supplier but also a trusted partner in the industry. Leading manufacturers choose us because we provide hot melt adhesive products that can meet the most demanding challenges.

Environmentally Friendly & Non-toxic

No Carbonization after Continuous Use

Fast Bonding

High Strength

Aging Resistance

Thermal Stability

EVA Hot Melt Adhesive

It has become a popular choice for filter manufacturing due to its excellent bonding strength and flexibility. It is compatible with various substrates, and is suitable for bonding different types of filters. It relatively inexpensive and cost-effective.

PO Hot Melt Adhesive

It is known for its excellent bonding strength, high flexibility, and moisture resistance. It is suitable for manufacturing filters exposed to humid environments. It is slightly more expensive, however, it has good bonding strength and strong anti-yellowing properties, making it popular among high-end customers.

PA Hot Melt Adhesive

It is known for its excellent bonding strength, even at high temperatures. It is an ideal choice for high-temperature applications and is commonly used in filter manufacturing where the filter will be exposed to high temperatures.

Air filter center line adhesive

Fuel & oil filter paper pleating adhesive

Air filter paper pleating adhesive

Cabin air filter edge banding adhesive

Fuel filter paper pleating adhesive

| Code Number | Material | Melting Speed | High Temperature Resistance (°C) | Low Temperature Resistance (°C) | Viscosity | Softening Point (°C) | Recommended Working Temperature (°C) |

|---|---|---|---|---|---|---|---|

| LMHB150 | EVA | 5–8 seconds | 80 | – | 5500–8500 cP (180 °C) | 95±5 | 150–170 |

| LMHP232 | EVA | 3–5 seconds | 100±5 | – | 5500–8500 cP (180 °C) | 110±5 | 160–180 |

| LMHM180 | PO | Moderate | 100 | -20 | 6000–10000 cP (180 °C) | 110±10 | 110–120 |

| LMHH190 | PA | 3–8 seconds | 220–240 | – | 1600–3200 cP (210 °C) | 175±5 | 180–200 |

| LMFT412 | PA | 8–10 seconds | 220–240 | – | 15000-20000 cP (200 °C) | 120±5 | 180–200 |

| Note: The above are some common specifications and parameters. If you do not find a suitable product, you can contact our sales representative for detailed inquiries. Contact Us | |||||||

In the field of hot melt adhesives for automotive filters, the requirements for hot melt adhesives vary greatly depending on the working environment, necessitating careful selection based on specific conditions. Specifically, the selection of hot melt adhesives should be considered from the following perspectives:

We will select an appropriate product type for you based on your actual application and provide full-process technical support. We are committed to providing you with the most professional service and the highest quality products, and we look forward to cooperating with you. If you have any questions or needs, please feel free to contact us.

PLM Filter provides customized solutions for automotive filter manufacturers (including sample testing and customization) to meet the specific needs of customers.