For hydraulic filter element end cap

The main component of two-component filter adhesive is polyurethane, a polymer known for its flexibility after curing. It includes two separate formulations designed to be used in combination. Our two-component filter adhesive is specially developed and designed for sealing and bonding plastic or metal end caps in products such as hydraulic oil filters, oil filters, fuel filters, and air filters. It features high bonding strength, chemical resistance, low-temperature curing, good elasticity and flexibility, and can adapt to the complex working conditions of automotive filters, resist vibration and impact. Besides, it is safe and reliable, and has a simple application process.

As an expert in the field of adhesives, PLM Filter has always worked with partners to develop innovative solutions that better meet industry applications, and we are always at your service.

Solvent-Free

Excellent Water Resistance

Excellent Acid & Alkali Resistance

Resistance to High & Low Temperature Changes

Excellent Shock Resistance

High-Strength Bonding Performance

For hydraulic filter element end cap

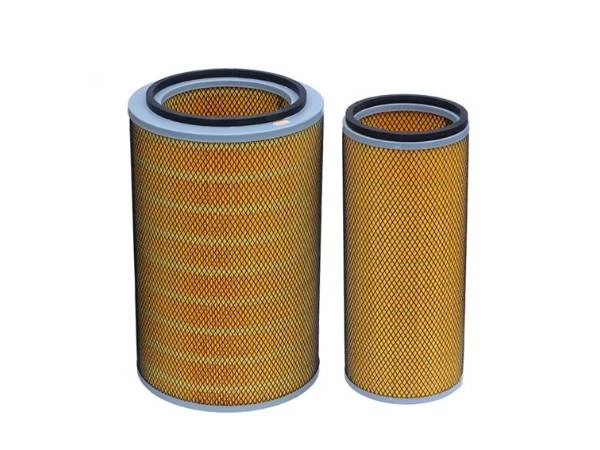

For air filter end caps

For fuel and oil filter end caps

| Model | LM1541 | LM1641 | LM1645 | LM1841 | |

|---|---|---|---|---|---|

| Tensile Strength (Steel-Steel) (MPa) | > 4.0 | > 4.0 | > 4.0 | > 4.0 | |

| Tensile Shear Strength (Steel-Steel) (MPa) | > 3.0 | > 3.0 | > 3.0 | > 3.0 | |

| Tensile Strength of Paper Filter Element (C0304) N | > 700 | > 700 | > 700 | > 700 | |

| A:B | 5:1 | 6:1 | 6:1 | 8:1 | |

| Liquid Color | A | White | White | White | White |

| B | Brown | Brown | Brown | Brown | |

| Volatile Content (%) | A | ≥ 98 | ≥ 98 | ≥ 98 | ≥ 98 |

| B | ≥ 98 | ≥ 98 | ≥ 98 | ≥ 98 | |

| Density (g/mL) | A | 1.35±0.1 | 1.4±0.1 | 1.3±0.1 | 1.4±0.1 |

| B | 1.22±0.05 | 1.22±0.05 | 1.22±0.05 | 1.22±0.05 | |

| Viscosity (mPa·s at 25 °C) | A | 3000–6000 | 3000–6000 | 3000–6000 | 3000–6000 |

| B | 200–250 | 200–250 | 200–250 | 200–250 | |

| Note: The above information is for reference only. For specific selections, please consult our sales staff. Welcome to Consult | |||||

| Application | LM1541 | LM1641 | LM1645 | LM1841 |

|---|---|---|---|---|

| Hydraulic Oil Filters | √ | |||

| Dust Filter Elements | √ | √ | √ | |

| Industrial Filters | √ | √ | √ | |

| Oil Filters | √ | √ | ||

| Fuel Filters | √ | √ | ||

| Air Filters | √ | √ | ||

| Air Cleaners & Purifiers | √ |

In the field of two-component filter adhesive for automotive filters, selecting an appropriate product type requires full consideration of various factors, such as bonding strength, impact resistance, and operability. To help you quickly find the product type you need, we will make recommendations based on your specific application and provide full-process technical support. Specific factors to consider when choosing an adhesive:

We have carefully selected three types of products that meet the requirements: LM1541, LM1641, and LM1645. Among them, LM1641 offers the best cost-performance ratio, LM1541 has the strongest bonding capability, and you can choose based on your specific application. We are committed to providing you with the most professional services and the highest quality products, and we look forward to cooperating with you. If you have any questions or needs, please feel free to contact us.

PLM Filter provides customized solutions for automotive filter manufacturers to meet the specific needs of customers.