End Cap Bonding

The bonding between the metal or plastic end cap and the filter element usually uses thermosetting adhesives, as well as two-component PU adhesives or epoxy adhesives, or PA hot melt adhesives.

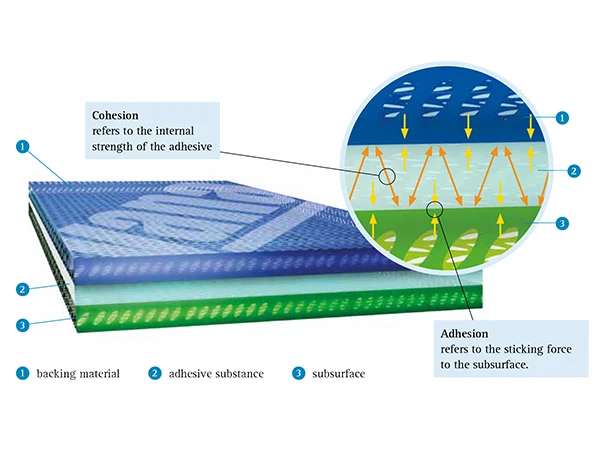

What is an adhesive? An adhesive, also known as a glue, binder, or bonding agent, is a substance that can join two or more parts or materials together through adhesion and cohesion at the interface, commonly referred to as glue.

This diagram shows the various forces acting on an adhesive bond joint. Cohesion refers to the internal strength of the adhesive. Adhesion (adhesive force) refers to the adhesive force to the substrate. Generally speaking, the higher the adhesion, the lower the cohesion. The optimal balance between cohesion and adhesion is crucial for permanent adhesion.

Adhesive Raw Materials

The main components of adhesives include binders, curing agents, tougheners, diluents, fillers, modifiers, etc.

Adhesive Classification

Classified by appearance

Classified by curing method

Classified by composition

Adhesive Application Range

Building structures, building sealing, automotive field, packaging field, electronics field, footwear field, etc. Today, we mainly explain the automotive field, especially adhesives for automotive filters.

Types of adhesives for automotive filters

Adhesives for automotive filters are classified based on whether they contain solvents:

Classified by main components:

Classified by application:

Application of Adhesives for Automotive Filters

The filter adhesives currently on the market are quite complex, including two-component PU adhesive, single-component PVC adhesive, EVA hot melt adhesive, PA hot melt adhesive, PO hot melt adhesive, epoxy adhesive, acrylic adhesive, etc.

End Cap Bonding

The bonding between the metal or plastic end cap and the filter element usually uses thermosetting adhesives, as well as two-component PU adhesives or epoxy adhesives, or PA hot melt adhesives.

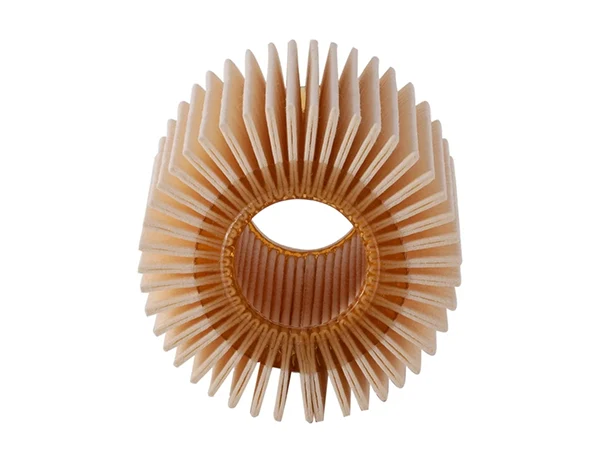

End Caps & Frames Molded by Casting

Directly molded using PU adhesive, this adhesive also consists of two components used in a certain ratio, with component A being polyether (foaming agent) and component B being liquefied MDI (polyurethane).

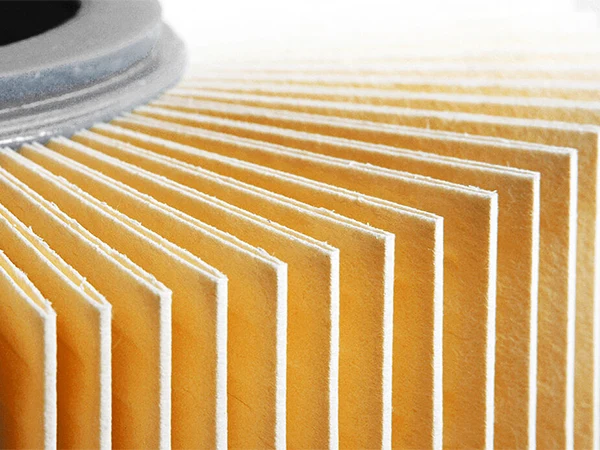

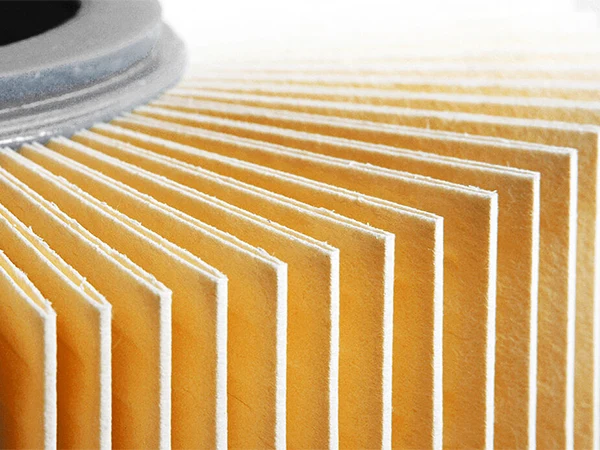

Filter Element Bonding

The bonding of filter paper to filter paper, depending on the requirements of different vehicle models, may use EVA hot melt adhesive, PO hot melt adhesive, or PA hot melt adhesive, with PA hot melt adhesive used for higher temperature resistance requirements.

Reinforced Spine Glue Line for Air Filter

For air filters in small cars such as sedans and SUVs, to reinforce the toothed filter element, several longitudinal glue lines are applied to the filter element, forming a solid whole. These glue lines are now mostly made with hot melt adhesives, such as EVA hot melt adhesive and PA hot melt adhesive.

Rubber Seal Ring & Metal Cap Bonding

In larger air filters, the end cap of the filter is metal, and a rubber seal ring is needed outside the metal cap. The bonding of this seal ring to the metal cap is usually done with β-hydroxy acrylate adhesive, although EVA hot melt adhesive is also used.

Development Trends of Adhesives for Automotive Filters

With the rapid development of China's automotive industry, adhesives for automotive filters have also developed accordingly. With the requirements for lightweight, noise reduction, vibration damping, low emissions, low VOC, and low odor in China's automotive industry, adhesives for automotive filters have also acquired new characteristics and development directions.