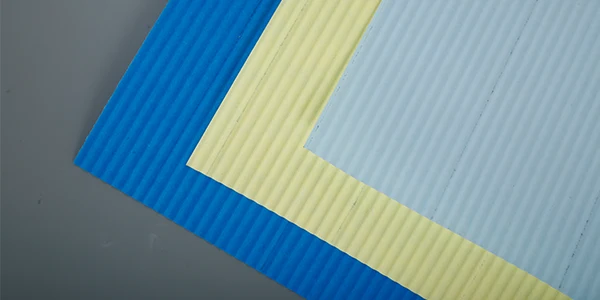

Mechanical corrugation forms a three-dimensional wavy structure, increasing the effective filtration area by 300% compared to plain filter paper.

Automotive filter paper is designed to operate continuously under demanding conditions, including high temperatures, high humidity, and oil contamination, thereby requiring exceptionally high standards for both materials and manufacturing processes. Our filter paper is engineered for use in automotive air, oil, and fuel filters, delivering superior performance, reliability, and service life that significantly exceeds standard filter paper. The following outlines its key advantages and selection guidelines.

Material Composition

Filter Paper Types

Mechanical corrugation forms a three-dimensional wavy structure, increasing the effective filtration area by 300% compared to plain filter paper.

Surface pore size is smaller than the inner layer, enabling a dual mechanism of 'deep interception and surface fine filtration.'

Constructed from two or more layers of filter paper pressed together, enabling functional stratification.

Manufacturing Process

| Process steps | Automotive Filter Paper Process Characteristics | Standard Filter Paper Process Characteristics |

|---|---|---|

| Pulping | Multi-stage screening removes short fibers (fiber length ≥ 2.5 mm) | Permitting retention of 20% short fibers |

| Resin impregnation | Segmented impregnation and infrared curing (resin distribution CV < 5%) | Single impregnation with natural air drying |

| Drying | Hot air penetration drying (moisture content controlled at 0.5%–1.2%) | Conventional drum drying (moisture content 2%–3%) |

| Surface treatment | Plasma graft modification (contact angle > 110°) | No special oleophobic treatment |

| Quality inspection standards | Compliant with ISO 4548-12 fuel filter testing standards | In accordance with standard industrial filter paper standards |

Performance Characteristics

Selection Reference

With over 30 years of experience in the filter industry, we are highly attentive to our customers’ stringent procurement requirements. The following represents the performance level of our filter paper for your reference.

Material Traceability

DSC thermal analysis report of wood pulp is required (glass transition temperature ≥ 180 °C).

Process Validation

Evaluate resin impregnation uniformity (using microscopic imaging to detect penetration rate deviations).

Performance Testing

Engage third-party testing for filtration ratio (β value ≥ 200) and contaminant holding capacity.

Environmental Simulation

Conduct thermal shock tests from -40 °C to +150 °C (100 cycles without cracking).

Mass Production Assurance

Verify IATF 16949 system certification and process capability index (CPK ≥ 1.33).

Contact Us

Leiman is currently developing innovative solutions including nanocellulose-reinforced filter paper (with a 40% increase in tear resistance) and intelligent coated filter paper (featuring pressure sensing for blockage warnings). We recommend staying updated on material innovations to maintain product competitiveness. To request the Automotive Filter Paper Performance Benchmarking White Paper or discuss customized development solutions, please contact us.