Intake Filter Material Treatment: Binders & Additives

The production process and treatment of intake filter materials are more complex and detailed compared to exhaust filter materials. It not only includes various binders, additives, and fibers as raw materials but also involves many web-forming technologies and process flows. Today, we mainly study the treatment of intake filter materials, which primarily involves the use of binders and additives.

Binder

The main purpose of using binders and additives in filter media is to enhance the media and provide important properties such as stiffness, tear strength, modulus, dimensional stability, water resistance, downstream processing performance, heat and temperature resistance, chemical resistance, environmental exposure resistance, and durability during use.

Formaldehyde Resin

Formaldehyde resin has three main forms: phenolic resin/phenolic plastic, melamine formaldehyde resin, and urea formaldehyde resin. In applications, melamine formaldehyde resin and urea formaldehyde resin are used as wet strength agents in the wet forming process; solvent-based phenolic resin is used as a saturant in wet-formed filter paper.

Latex Resin

Latex resin is an emulsion of polymer particles in water. In addition to the base polymer, the emulsion also includes a surfactant system to stabilize the emulsion. When used in non-woven filter media, other additives are also added to enhance the polymer and achieve additional properties.

Additive

Adsorbent Material

Some adsorbent materials that may be used for non-woven filters: activated carbon; Activated alumina, with a small surface area, but a good substrate for certain impregnation processes; Synthetic sodium aluminosilicate (zeolite), with pore sizes can be designed for specific separation functions; natural zeolite; ion exchange resin; silica gel.

Flame Retardant

The function of flame retardants is to inhibit the oxidation reactions that lead to combustion. For example, halogenated compounds (including chlorine and bromine) will release free halogen ions (C- or Br- ) when exposed to high temperatures, which will then react with hydrocarbon molecules to form HBr and/or HCl and inhibit the oxidation reaction process.

Water Repellent

The filter media is made water-resistant by using hydrophobic materials on the surface of the media. This function can be achieved by using waterproof fibers or waterproof coatings. For example, drivers will notice that when raindrops hit the car roof, they form into spheres and simply roll off, which is an example of the use of waterproof materials.

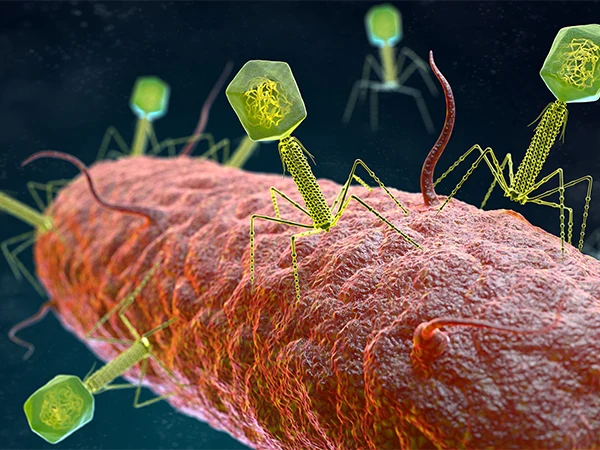

Antimicrobial Agent

Antimicrobial agents can inhibit the growth of microorganisms on the surface of the filter media and the surface of the internal fibers. Antimicrobial agents can be incorporated into the media as a surface treatment, or they can be a component of the fibers, such as silver, zinc, copper, etc.