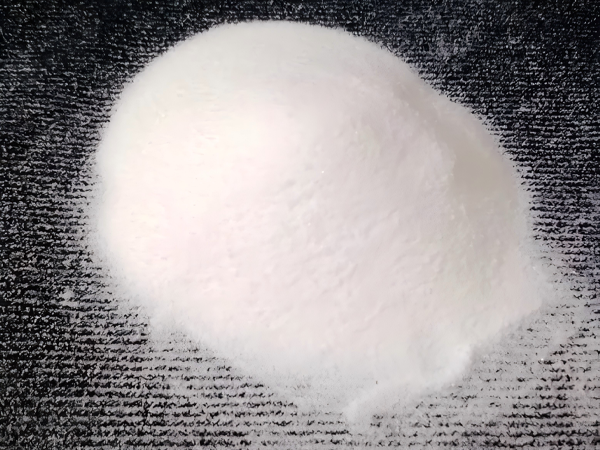

Industrial Hot Melt Adhesive with High Strength and Heat Resistance

Industrial hot melt adhesive is a thermoplastic bonding material widely used across packaging, automotive, construction, hygiene, textiles, and electronics. It is classified by chemical composition, each with distinct performance characteristics and application areas.

Main Types

EVA (Ethylene-Vinyl Acetate)

With good adhesion, flexibility, and cold resistance but limited strength and poor heat and oil resistance, this adhesive is widely used in bookbinding, woodworking, carton sealing, shoemaking, and furniture edging.

Polyolefin (PE/PP)

Non-toxic, chemical-resistant, and low in water absorption, this adhesive is suitable for porous materials though slower to set, and is commonly applied in food packaging, non-woven laminating, automotive carpets, and box sealing.

Polyester (PET/PES)

Featuring high strength, impact and heat resistance up to 150 °C, and excellent insulation though requiring specialized equipment due to high viscosity, this adhesive is used in garment interlining, electronic parts fixing, automotive interiors, and construction surfaces.

Polyurethane (PUR/TPU)

TPU offers elasticity, strength, and efficiency for high-speed production, while PUR provides moisture-curing durability with heat and water resistance up to 180 °C, making them ideal for automotive wiring, structural bonding, and premium furniture edging.

Styrenic Block Copolymers (SBS/SIS)

Elastic with good low-temperature performance, and with SIS offering low viscosity for precise coating, this adhesive is widely used in hygiene products, pressure-sensitive labels, and automotive interiors.

Polyamide (PA)

With high strength and resistance to heat, oil, and chemicals, this adhesive is commonly used in automotive engine parts, electronic encapsulation, and footwear bonding.

Key Application Areas

- Packaging: EVA and polyolefin dominate box and food packaging, ensuring fast curing.

- Automotive: PUR and PA used for interior bonding, wiring, and heat-/oil-resistant parts.

- Furniture & construction: EVA and PUR applied in MDF/PVC edge banding and structural adhesion.

- Hygiene & textiles: SBS/SIS for diapers and sanitary products; EVA for garment interlinings.

- Electronics: Polyester and polyamide for insulation and component encapsulation.

Selection Parameters

- Softening point: Determines heat resistance (automotive adhesive requires > 100 °C).

- Viscosity: Affects coating efficiency (low viscosity enables precise spraying).

- Open time: PUR provides longer assembly time; EVA sets within seconds.

- Environmental safety: 100% solid, solvent-free, compliant with food and medical standards.

Industry Trends

The hot melt adhesive industry is moving toward higher performance and eco-friendly solutions, highlighted by heat-resistant PUR grades, gentle medical formulations, and lightweight options for EV applications.