The filter cartridge is the filter element of the cartridge dust collector and is one of the most important components. It consists of pleated filter material, a support frame, upper and lower end caps, adhesive, and a sealing ring, with the filter material being the core of the filter cartridge. The selection of filter material needs to follow several basic points.

- High hardness, can withstand a certain negative pressure after pleating;

- Not too brittle, and can withstand long-term pulse action;

- Not too thick, as it is not conducive to increasing the filtration area;

- Good stability, and can adapt to conditions such as humidity and temperature;

- Environmental protection, the filter material must not release harmful substances.

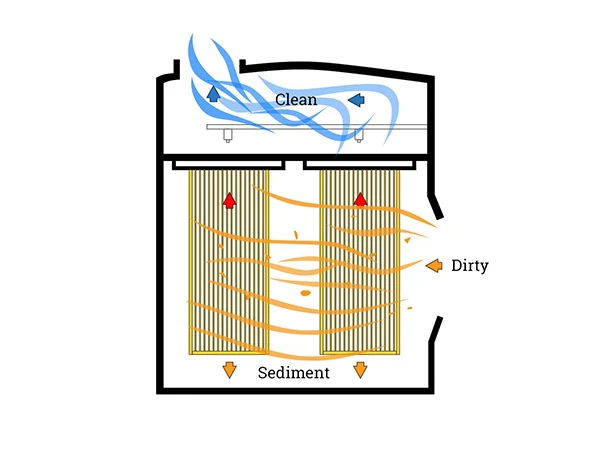

Filtration Mechanism

- Thickening the dust layer

When a new filter cartridge is first installed in the dust collector, a large amount of dust quickly adheres to the surface of the filter material, and the dust layer continuously thickens. During pulse back-blowing, a large amount of rapid airflow enters the inner frame of the filter cartridge, generating an instantaneous impact force that causes the filter material to vibrate and bend, peeling off the outermost dust layer on the surface of the filter material and expelling it with the airflow, thereby achieving the effect of pulse cleaning.

- Forming initial dust cake

After cleaning, we hope that a stable initial layer of dust remains on the surface of the filter material and is not removed. This layer of dust is called the initial dust cake. It is the key to ensuring filtration efficiency, and it can maximally prevent subsequent dust from entering the core of the filter material, effectively protecting the filter material from clogging. This is the mechanism of surface filtration.

Precautions

Therefore, during cleaning, it is essential to ensure that cleaning is not excessive; otherwise, it will shorten the lifespan of the filter cartridge and cause emissions to exceed standards. However, when the cleaning effect is poor, the dust layer will continuously increase, causing the filter material to become severely clogged. This is also not the effect we expect to achieve, so pulse cleaning should be appropriate, neither excessive nor insufficient.

The situations encountered in actual working conditions are ever-changing, and a few simple filter materials can hardly meet the actual working demands. For instance, when dealing with flammable and explosive dust, it is necessary to avoid static discharge. Since chemical fiber (high insulation) filter materials easily accumulate static electricity, to prevent static discharge, the filter material needs to undergo anti-static treatment.

The main special functions of the filter material specifically for filter cartridges currently include: